With a reputation for rigorous procedures and practices, Zetica leads the UK for UXO detection

One of our primary considerations is improving safety through verification of results and clear communication of the actual effectiveness of any UXO detection undertaken.

Using our test site in Oxfordshire to train staff, verify that our proposed techniques are effective, and to trial newly available equipment, we maintain our cutting edge status in the industry.

TARGET TYPE AND DEPTH

UXO detection surveys can be either non-intrusive or intrusive.

To determine the most effective approach, consideration has to be given to a number of factors, primarily:

- Burial setting of UXO.

- Intended works.

- Type of UXO (e.g. size, ferrous or non-ferrous).

- Site conditions and access.

- Client’s risk tolerance.

If a detailed UXO risk assessment has been undertaken, this should inform an appropriate survey design.

Where shallow-buried UXO hazards are anticipated, a non-intrusive detection survey (where practical) is a proactive form of risk mitigation.

NON-INTRUSIVE UXO DETECTION SURVEYS

Zetica undertakes a range of non-intrusive UXO detection surveys.

A good detailed UXO risk assessment will confirm the anticipated ordnance on your site and inform an appropriate survey design.

Where ferrous ordnance is anticipated, we undertake magnetometer surveys using highly sensitive caesium vapour magnetometers. These can detect air-dropped bombs up to 6m depending on size and ground conditions.

Where low- or non-ferrous ordnance is anticipated, we undertake electromagnetic surveys.

We use a variety of techniques, uniquely a broadband electromagnetic system specifically designed for use on our towed platforms.

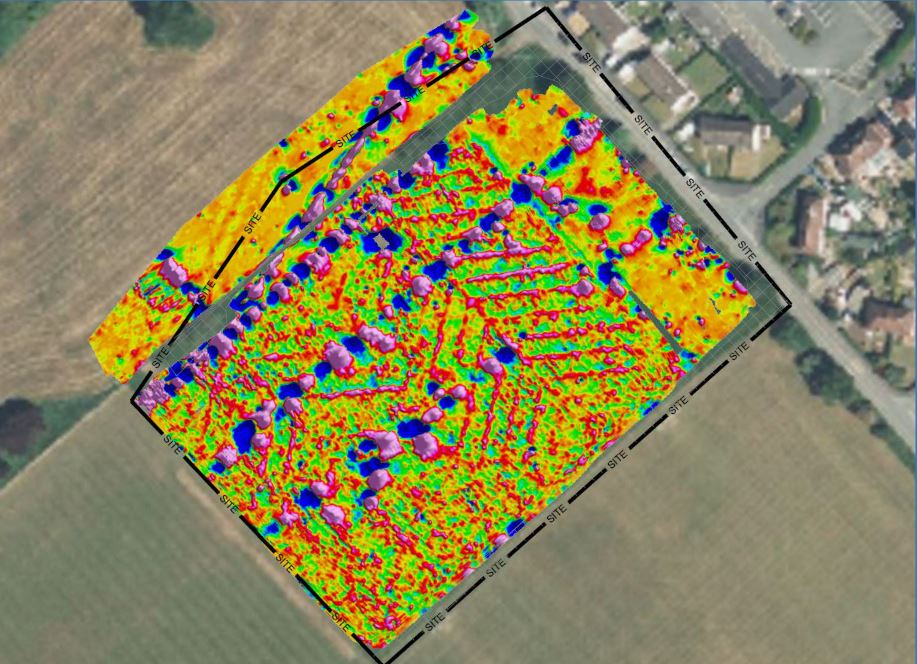

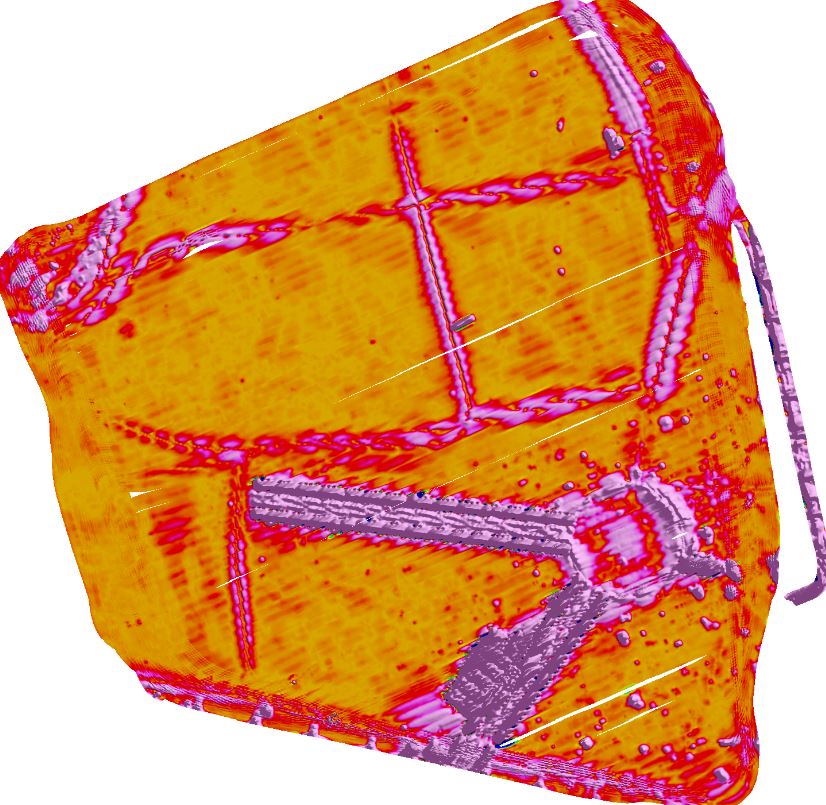

Where access allows we undertake our surveys using towed geophysical platforms. These have been designed in-house to cope with a wide variety of site conditions and terrains. This can allow for coverage up to 6-8 hectares per day.

Depending on the techniques used, in a single survey phase we can map:

- UXO

- Changes in geology, such as clay to gravel.

- Changes in groundwater conditions.

- Buried obstructions.

- Voids.

- Areas prone to collapse during excavation.

- Buried waste materials and infilled ground.

- Buried archaeological features.

- Existing cables, pipes and other utility services.

For further information on the full range of site investigation services Zetica offer, visit our group website.

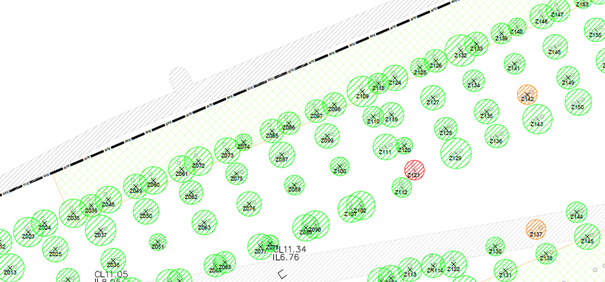

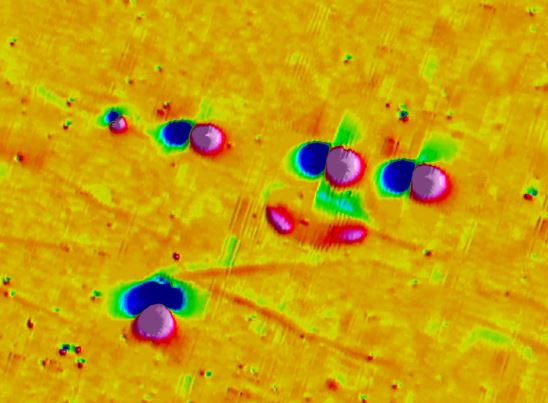

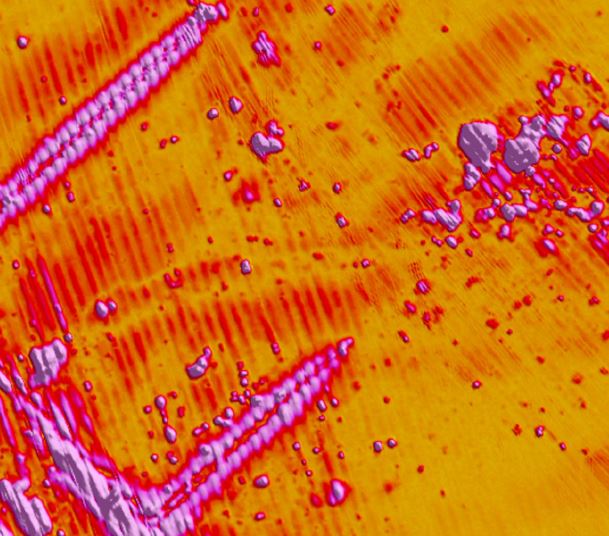

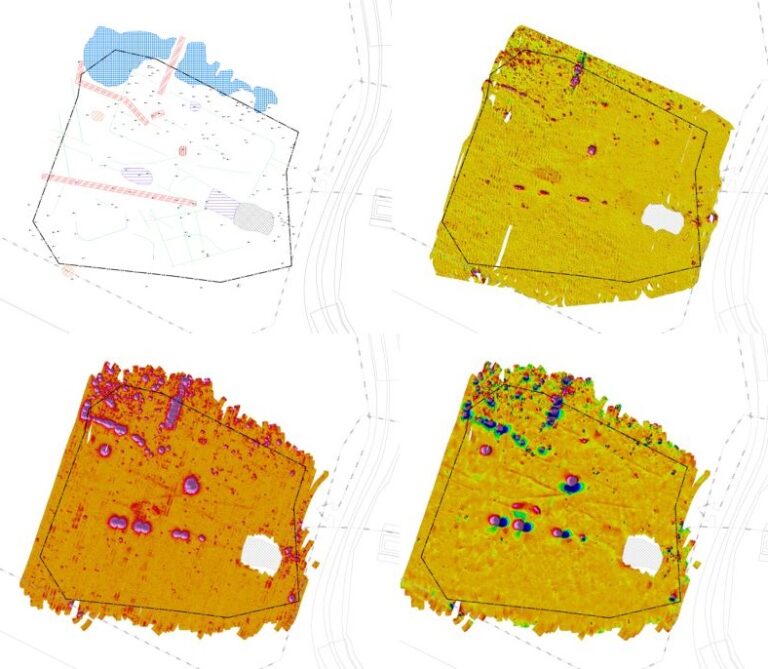

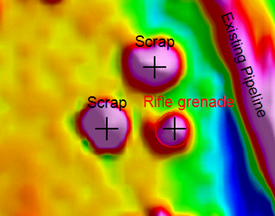

Use the slide bars above and to the right to reveal data from some of our non-intrusive detection surveys. In addition to isolated metallic anomalies ( which will be assessed as potential UXO targets or not), these surveys have also detected several other buried hazards. Linear features may be indicative of utilities or, in the example above, possible historic land drainage.

TARGET SELECTION/DETECTABILITY

A key aspect Zetica promotes within the industry is detection assurance. This provides safety by ensuring that on completion of any survey, any residual UXO hazard is understood.

Our thoroughness lowers the chances of UXO being unexpectedly discovered during site development.

As part of this, Zetica UXO has a robust quality control process for UXO detection surveys. This includes modelling and assessment of potential UXO targets through a seed test (burying an object of comparable size to target UXO) and confirming the limits of UXO detection at the site.

Wherever feasible, we assess each anomaly for its characteristics, its size/amplitude, its likely depth. Where appropriate, we undertake forward modelling to better establish its likelihood of being UXO.

Depending on the results of any UXO detection survey, a target investigation may be required to further mitigate the potential UXO risk on your site.

Our quality control procedures during the survey allow for better target discrimination, typically reducing the amount of intrusive investigation required.

Where time or access does not allow for a mapped geophysical survey, we can undertake UXO clearance in real-time. This would involve an Explosive Ordnance Clearance (EOC) team scanning areas of proposed works for readily detectable targets. These can either be avoided or immediately investigated.

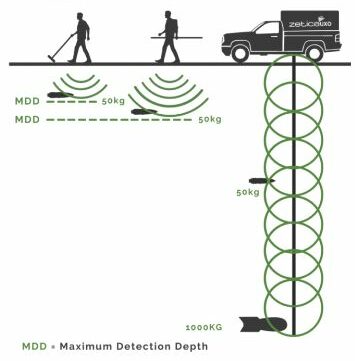

DEEP UXB DETECTION

Where there is a hazard from UXB at depth, we can provide deep UXB detection surveys to ensure drilling and piling works proceed safely.

There are two main systems:

MagDrill – this is a drilling-based technique which allows for a magnetometer to be lowered into a borehole at intervals as it is progressed. This is appropriate for clearing small numbers of positions or where ground conditions preclude MagCone probing (see below).

MagCone – this is a CPT-based system which allows a magnetometer probe to be advanced into the ground at a borehole or pile location. This is suitable for soft, cohesive ground conditions and is typically much quicker than MagDrill.

In both instances, the magnetometer can detect potential ferrous anomalies within a radius of the probe. It is important that any geophysical data collected is reviewed as a back-office task by an experienced geophysicist (see Quality Control page).